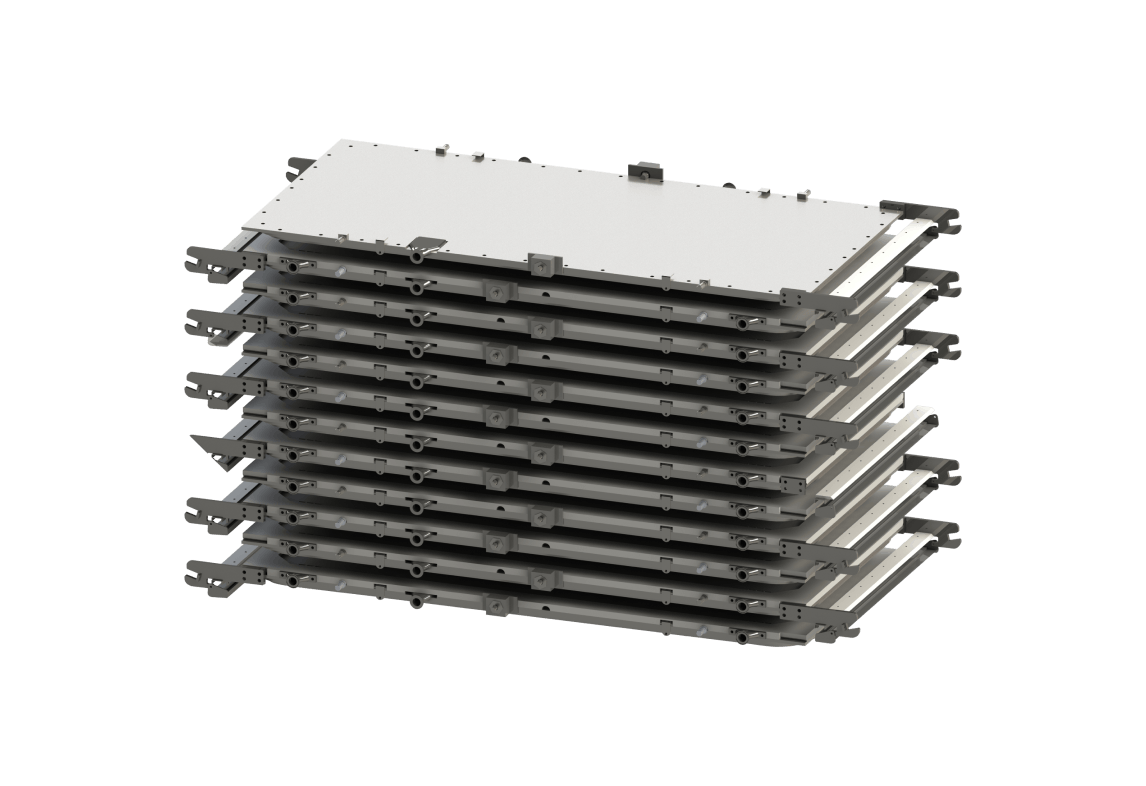

The plate layer of the fully automatic vertical filter press is the component that completes the filtration, providing a closed chamber for feeding, diaphragm extrusion, air blowing, etc.

The plate layer body is made of ultra-high molecular material, and the main board and the filtrate frame are assembled to form a top-down stacked structure.

The slurry enters through the feed pipe on the main board, and the filtrate flows out through the filtrate port on the main board.

- BLZG

- TPF

- HVPF

- LZB

- PF

- MQLY

- Larox

The plate layer should be checked for flatness on a daily basis.

Be careful not to perform cavity extrusion. The extrusion pressure of the vertical filter press is very high, which will cause the plate layer to deform.

If the plate layer has deformed, it is necessary to check whether it is caused by cavity extrusion in time and replace the relevant plate layer of the vertical filter press.