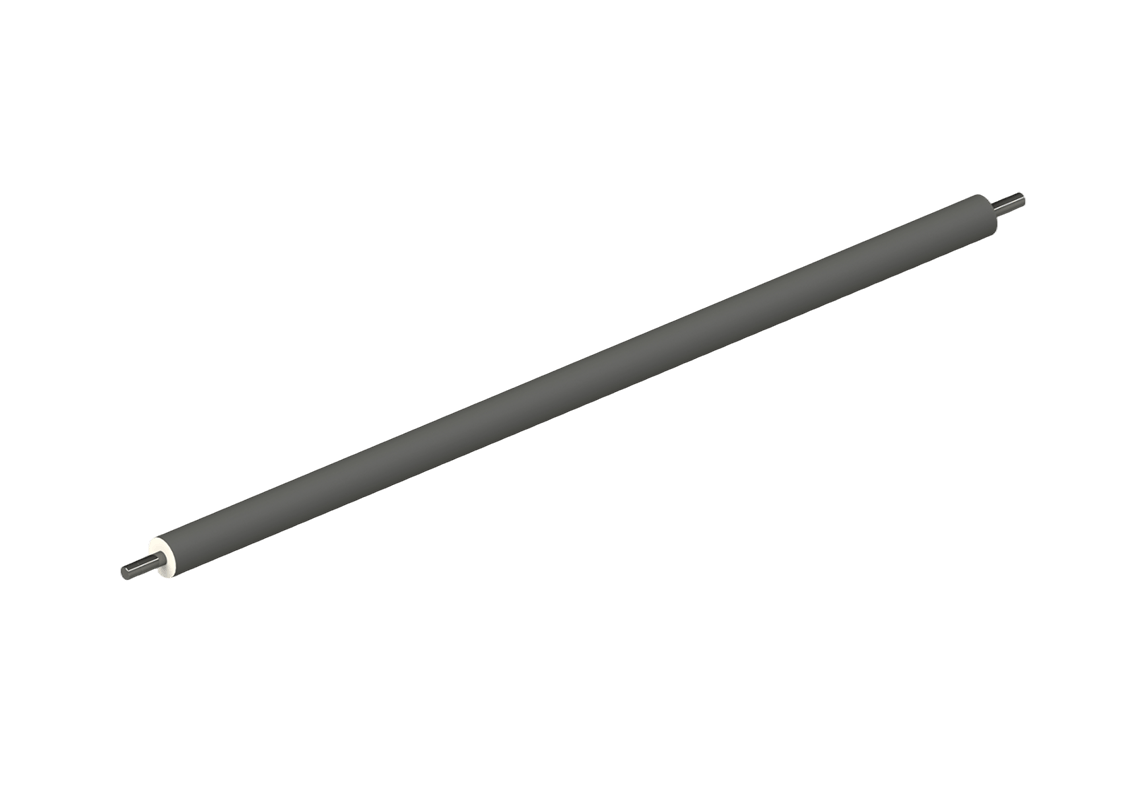

The rubber-coated rollers of belt vacuum filters can be divided into filter cloth pressure rollers, belt lower rollers, redirecting rollers, deviation correction rollers, tensioning rollers, etc. according to different uses. Rubber-coated rollers are usually composed of metal inner cylinders, outer rubber layers, shaft heads, etc. Rubber, fluororubber, silicone rubber and other materials can be used according to different working conditions. The shaft heads are generally made of 45# steel, SS304 and other materials.

The filter cloth pressure roller presses the filter cloth tightly on the rubber filter belt to ensure the fit between the filter cloth and the rubber filter belt, preparing for the inflow and filtration of the slurry.

The belt lower roller refers to the roller that supports the movement of the rubber belt under the vacuum belt filter, also known as the belt lower roller. The belt upper roller is generally a roller with a built-in bearing made of polymer plastic material, which is different from the belt lower roller.

The redirecting roller refers to the roller that controls the longitudinal movement of the filter cloth. It is the turning point of the filter cloth, which realizes the correction of the direction of the filter cloth by the roller.

The deviation correction roller refers to the roller that controls the lateral movement of the filter cloth. It is arranged at the lower part of the frame arranged at the drive end, close to the filter cloth turning point. The deviation correction device changes the front and rear position of one end of the redirection roller to realize the roller's correction of the filter cloth's direction.

The tensioning roller is a roller that controls the tension of the vacuum belt filter cloth by adjusting the tension of the roller. Conventional tensioning rollers control the tension of the filter cloth by adjusting the position of the shaft head in the vertical direction. The gravity roller specifically refers to a roller that controls the tension of the filter cloth by the roller's own gravity.

- DU

- RBV

- HBF

It is necessary to inspect the surface of the rubber-coated roller to see if there are any cracks or breaks on the surface of the roller, and replace the roller with serious problems in time;

Observe the operation of the roller, paying special attention to whether the roller is stuck, delayed, or stopped, and pay attention to whether it is caused by scaling or crystallization of the material at the bearing position. The relevant bearings should be lubricated or replaced in time.